Project Overview

C-BORD Toolbox

Passive Neutron and Gamma Detection Sub-systems

In the C-BORD project a new generation of Container Inspection Systems is being developed. This will combine five technologies to provide advance inspection capabilities. Part of the project is dedicated to developing passive neutron and gamma detection sub-systems to be evaluated in use cases.

The main aims for these passive detection systems are:

- Develop commodity and intelligence enhanced mobile / re-locatable passive detection systems with enhanced NORM classification, isotope identification (PVT and NaI versions) He-3 free neutron detection systems and advanced, intuitive visual detection information to integrate into C-BORD data-fusion systems.

- Demonstrate feasibility of using X-ray enhanced manifest data (automated X-ray generated intelligence e.g., tobacco detection algorithms) for enhanced tobacco detection, NORM classification and isotope identification.

- Demonstrate capabilities provided by reconstructed spectra using de-convolution enhancement on low and high energy photons and the quantitative nature of the technique for use in a range of applications.

C-BORD Passive Detection Features

- Fully stabilised crystal and PVT spectrometers that provide very low false alarm rates (<1:10,000) and low nuisance alarm rates on Naturally Occurring Radioactive Materials (NORMs)

- High sensitivity He-3 free 6LiZnS detectors

- Integration of new scintillation materials which offer increased material discrimination

- Detection system adapted for non-stop, higher speed lorry transits with SNM specific and material discrimination capabilities

- Advanced passive gamma and neutron screening component technologies will be adapted and optimised to leverage the signal discrimination capabilities of other C-BORD sub-systems

- Targeted inspection for nuclear materials and decay chain verification in collaboration with X-ray inspection, rapidly re-locatable TNIS and Photofission

C-BORD Advanced Detection Systems

| Mobile Detection Systems | Radiation Portal Monitors | Relocatable Portal Monitors |

|

|

|

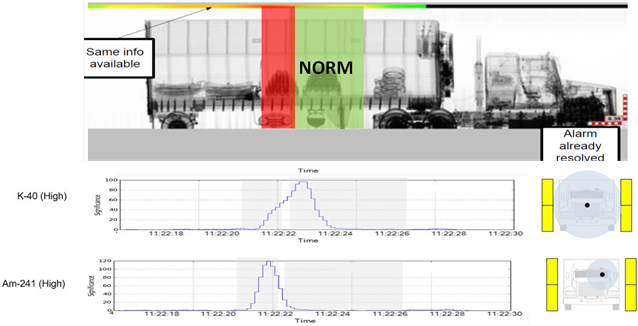

C-BORD Data Fusion

- Radiation detection data

- X-ray images enhanced user feedback

- Enhanced threat location

- Material categorisation

- Material identification

- Manifest enhanced user feedback

In the C-BORD project a new generation Container Inspection System is foreseen: It results in an advanced system, combining X-ray techniques capable of localizing objects inside a large volume (cargo container) at a high rate, and additional techniques more sensitive to specific substances, such as the Passive Technologies, the Tagged Neutron Inspection Systems, the Photo-fission technologies, and sniffers.

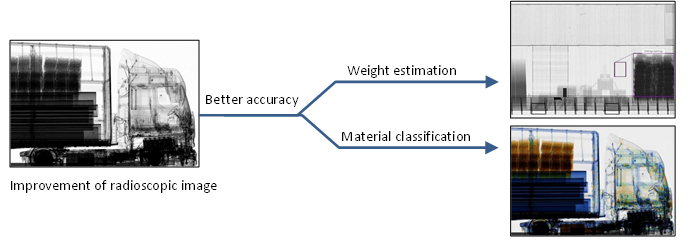

The C-BORD project is also an opportunity to improve X-ray techniques, particularly with regard to the accuracy of the material discrimination and also to help the image interpretation (Assisted / Automatic Target Recognition)

C-BORD X-ray Techniques

- The X-ray techniques have developed significantly over the past 20 years for cargo screening. They include an ability to classify materials and objects according to the atomic number Z. Like any radiographic technique used in medical diagnosis, industrial control or luggage screening, they allow visualizing the inside of a truck or container.

- The strength of the X-ray techniques lies in their ability to provide and localize shapes and chemical information of objects in a cargo container at a rather high speed. However, it consists in the projection of a 3D volume (cargo container) on a 2D plane overlaying all the plans and all thicknesses. This results in a mixing of shapes and materials inevitably bringing, in some locations, a bit of confusion and ambiguities. Moreover these methods are thus poorly sensitive to specific substances.

- Some typical values:

- Freight type: Containers, trucks, cars, vans, trains

- Scanning speed: From 1 to 60 km/h

- Image acquisition time: 45 sec (Scan mode) and 10 sec (Pass-thru mode)

- Image spatial sampling: of the order of 5 mm x 5 mm.

C-BORD X-ray Technology Improvements

- Global X-ray image improvements

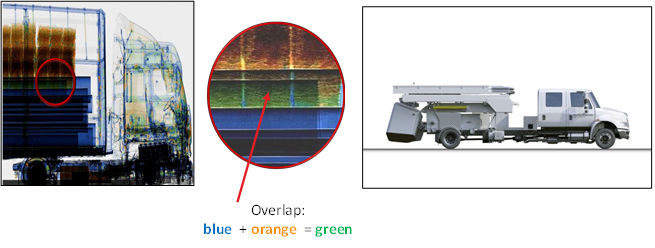

- Chemical separation of overlapping objects

- Improved material classification in the organic range

- Material discrimination for low dose systems

- Improvement of the accuracy of X-ray images in terms of transmission measurements (hardware and software means):

- Attenuation corrected from the effects of the scattered radiation

- Attenuation corrected from the effects of the variation of the dose and energy of the incident beam

- Improvement in material classification:

- Solution to the problem of overlays

- Increase of the number of discrimination classes (organic category)

- Development of HEMD on low dose and low weight systems (less than 15 tons)

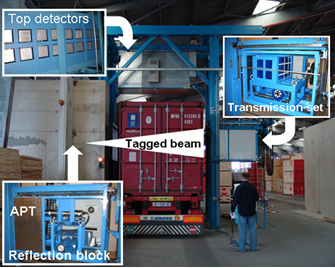

In the C-BORD project a new generation of Tagged Neutron Inspection System (TNIS) for cargo containers is foreseen, the first Rapidly Relocatable Tagged Neutron Inspection System (RRTNIS).

The RRTNIS will be a second-line system to be used on sealed containers, enabling the detection of explosives, illicit drugs and chemical agents in a suspect voxel (elementary volume unit).

The TNIS Measurement Technique

- The early system named Tagged Neutron Inspection System (TNIS) [1] uses an associated-particle sealed neutron generator to detect explosives or other threat materials concealed in cargo containers.

- The neutron generator, with a built-in segmented alpha particle detector, is used to produce a 14 MeV neutron and an alpha particle through the D+T fusion reaction.

- The position of the alpha particle defines the direction and time of the neutron emission, since the two particles are emitted simultaneously and almost back-to-back.

- Gamma rays induced by neutron inelastic scattering on the elements of the cargo material are detected in coincidence with the alpha particle. The time delay between alpha and gamma detection determines the depth in the container where the neutron interaction took place.

The TNIS New Generation Design

- The experience gained in past EU projects such as EURITRACK [2], ERITR@CK [3] and national projects such as SLIMPORT [4] and UNCOSS [5] has shown the capability to determine the type of material present in a given point inside the cargo by remotely measuring the elemental ratios in that point (i.e. gamma rays emitted in fast neutron reactions characterize carbon, oxygen and nitrogen, which are the major components of explosives or narcotics).

- Second generation TNIS has advanced to the point where a rapidly relocatable system can be designed, taking advantage of recent electronics and neutron generator developments, especially in terms of compactness.

- Using the expertise gained with the previous projects, a high performance RRTNIS will be designed with a high-level user-friendly interface.

C-BORD RRTNIS Expected Innovations

- Integrate a recent, miniaturized, high-performance associated particle neutron generator;

- Be equipped with a newly designed compact and transportable shielding for radiation hazard, thus reducing the size of the restricted area;

- Optimize the duration of data-taking by using advanced information processing and state-of-the-art gamma detectors with enhanced energy resolution to improve identification of warfare agents and dangerous chemicals;

- Improve the analysis through enhanced de-convolution algorithms of the gamma spectra that will improve material identification algorithms;

- Include a new visual user interface, which will be crucial to improve TNIS capability in threat identification.

References

[1] S. Pesente et al. “Tagged neutron inspection system (TNIS) based on portable sealed generators, Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, Volume 241, Issues 1–4, December 2005, Pages 743-747

[2] EURITRACK project: http://www.euritrack.org

[3] C. Carasco et al. “In-field tests of the EURITRACK tagged neutron inspection system”, Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment Volume 588, Issue 3, 11 April 2008, Pages 397–405.

[4] D. Cester, et al., “Special nuclear material detection with a mobile multi-detector system”, Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment Volume 663, Issue 1, 21 January 2012, Pages 55–63

[5] C. Eleon, B. Perot, C. Carasco, D. Sudac, J. Obhodas, V. Valkovic, “Experimental and MCNP simulated gamma-ray spectra for the UNCOSS neutron-based explosive detector”, Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, Volume 629, Issue 1, 11 February 2011, Pages 220-229

WP 5 Photofission

The detection of SNM (Special Nuclear Material – mainly uranium and plutonium isotopes) is a crucial issue for homeland security applications in order to prevent illicit trafficking. Non-destructive techniques are well-suited to cargo container inspection particularly because they are non-intrusive and do not require opening the container, which is a time consuming and potentially dangerous process.

Non-destructive Methods

- Non-destructive passive methods are based on the detection of particles spontaneously emitted by radionuclides of interest, mainly gamma and neutron emissions. However, these passive emissions can easily be impacted by the presence of shielding around nuclear material and by the poor passive emission of actinides (especially for uranium isotopes).

- Non-destructive active methods dedicated to SNM detection are an efficient solution when non-destructive passive methods encounter this type of limitation.

The Photofission Techniques

- These active techniques are two-step processes based on the fission reaction:

- an irradiation step in order to irradiate nuclear material and produce fission reactions;

- a detection step dedicated to the measurement of prompt and delayed particles emitted by fission products.

- Fission reactions are induced by high-energy photons (exceeding 6 MeV energy) delivered by a linear electron accelerator (LINAC) and identified under the technical term “photofission”. This highly penetrating incident photon beam is well adapted to the analysis of cargo containers.

- Several previous developments showed the potential of using photofission techniques for cargo container scanning in the context of homeland security applications. For example, the DEMIP project led by CEA LIST was a proof-of-concept step in order to demonstrate the experimental feasibility of this approach on mock-up containers. The figure below shows mock-up containers used in the DEMIP project (left) and a view of the first active portal developed in DEMIP and dedicated to the control of mock-up containers (right).

Development of the First European Photofission Prototype

Based on this background know-how, a main technical issue of the C-BORD project is related to the development of the first European photofission prototype able to be deployed in a harbor environment. The objectives of this development are the following:

- Design a photofission system based on a 9 MeV LINAC and combining several specific sub-systems (delayed neutrons, prompt neutrons, high-energy delayed gamma-rays, SNM identification features)

- Improve sub-systems enabling detection of prompt and delayed particles emitted by photofission reactions

- Provide strong association concerning coupling between high-energy imaging techniques and photofission measurements

Deployment of the Prototype

Within the C-BORD project the final purpose of these developments will consist in the deployment of this non-destructive active system in the Rotterdam harbor. A crucial step of this final demonstration will be the integration of the photofission detection module in the current dual view X-ray imaging system set up in the Rotterdam harbor (two 9 MeV LINACs currently used for high-energy imaging purposes). The figure below showsan overview of the Rotterdam harbor (left) and the 9 MeV LINAC used for photofission measurements (right).

The C-BORD Technology Sub-System evaporation based detector will develop detection technologies for volatile chemicals that may be present in a container, giving warning of hazard or contraband. These are expected to complement X-ray imaging by enabling molecular specific detection (chemical information instead of physical properties), improving the discrimination power of the scanning system.

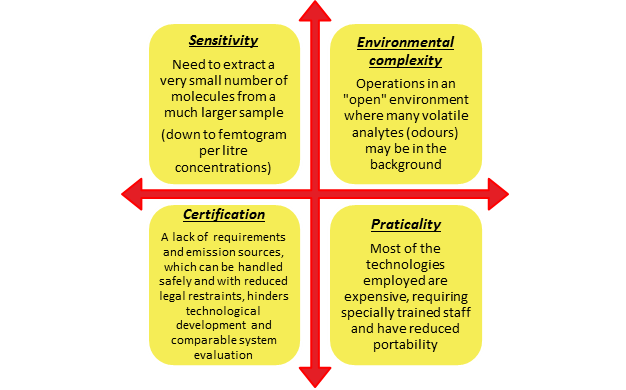

Previous sniffing approaches failed because of the complexity of the problem at hand:

The New Approach

- A new biomimetic approach to detection and identification of volatile chemicals shall be employed. This approach couples selective binding elements from biological systems – such as OBP (Odorant Binding Proteins) – with highly sensitive diamond microcantilever and machine learning. It also increases the selectivity of the detector by arranging the biosensors in an array.

- Each individual sensor in the array contains a specific OBP featuring a fairly broad selectivity to some chemicals or families of chemicals. The combination of the response of the sensors to a particular odour is translated into a pattern which is a fingerprint of the specific odour.

- A multiparametric software uses a database built during an initial calibration phase of the system to recognise and classify the volatile chemicals.

Expected Results

- New OBPs will be functionalized to detected analytes to cover the priority targets identified by customs.

- Sampling methods will be developed to allow the use of the device in the context of cargo screening. Many targeted substances have very low volatility or may be in sealed packets. Detection of these substances will require the integration of a large scale pre-concentration and sampling system. COTS large volume sampling methods as well as evaporation based detection systems will be investigated.

- Test standards and procedures will be designed. To date these are not available for large cargo inspection. Reliability of sniffing detectors (not only the C-BORD ones) will be increased by in-field evaluation and testing.

- A laboratory test-bed for the simulation of hidden illicit material in large volume cargo will be built for the evaluation of sampling systems and evaporation based detector technologies.

- Based on information from users, emission sources with defined emission rates for a variety of explosives and narcotics which can be handled safely with reduced legal constraints will be developed. This will include point sources as well as large volume or area sources which could be placed into large volume freight to mimic the emission of contraband.

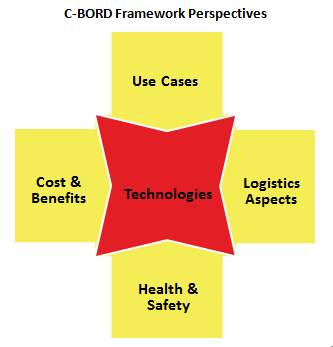

C-BORD Framework

Efficient NII (non-intrusive inspection) of containerized freight is critical to trade and society since freight containers are potential means for smuggling, drug trafficking, and transport of dangerous / illicit substances. NII technologies used today cannot cope with all targets under all circumstances with equivalent efficiency. Against this background the overall aim of C-BORD is to increase detection of illicit or dangerous material in containerized freight and deliver new capabilities against critical operational requirements and constraints which include:

- Increased throughput of containers per time unit

- Reduced need for costly, time-consuming and dangerous manual container inspections

- Lower false negative and false positive alarm ratios

In order to reach its ambitious goals C-BORD develops five technology pillars to enable next generation container NII at EU sea and land borders: The C-BORD project brings them to a live field trial in three use cases under real conditions at different border control points.

The C-BORD Framework provides a systemic response to key questions - functional, practical, logistical, safety and financial - that are related to the deployment of innovative NII technologies at EU borders in the future.

It will guide the practical usage of solutions developed by C-BORD in specific sea-border and land-border settings after project completion and support the decision of how to combine technologies for different needs. For this purpose the Framework will in particular focus on five interlinked Framework Perspectives.

C-BORD Technologies

- C-BORD works on five complementary innovative NII technologies: Advanced Radiation Management, Tagged Neutron Inspection, Photofission, Sniffer and Next Generation Cargo X-Ray

- The C-BORD Framework will document the achievements of the project beyond state of the art of current reference technologies by addressing e.g. detection levels and false alarm rates

C-BORD Use Cases

- C-BORD brings innovative NII technologies to application in an actual port and hinterland environment

- The C-BORD Framework will collect information and lessons learned from these use cases

- Hereby it serves as a knowledge repository to formalize the findings from the trials and their preparation

C-BORD Logistics Aspects

- In future, container inspection at border crossings will increasingly be an integral and fully automated part of the logistical flow of goods, in particular in high-throughput seaports

- This creates entirely new challenges for the technologies involved but also for required logistics processes

- The C-BORD Framework will develop logistical concepts to integrate the five innovative C-BORD technologies into port and hinterland processes and point out solutions to automate and optimize the container inspection chain

C-BORD Health & Safety

- Meeting health and safety regulations is an indispensable prerequisite for a future deployment of innovative NII technologies at EU borders

- The C-BORD Framework will describe barriers related to health and safety regulations for a full scale implementation identified during the project and indicate ways to overcome them

- In this context the licensing procedure for the deployment of technologies in the use case trials serves as a best case approach to take into consideration all safety and in particular health risks

C-BORD Cost & Benefits

- More efficient and high-performance NII technologies have potential for significant benefits, e.g. due to better detection performance, but will also require substantial investment and involve high life cycle costs

- The C-BORD Framework will provide a cost & benefit analysis to support informed decisions about deploying innovative NII in future

- This analysis of cost & benefits will serve as an effective decision support for policy and decision makers when deciding on the optimal mix of NII technologies for their particular needs

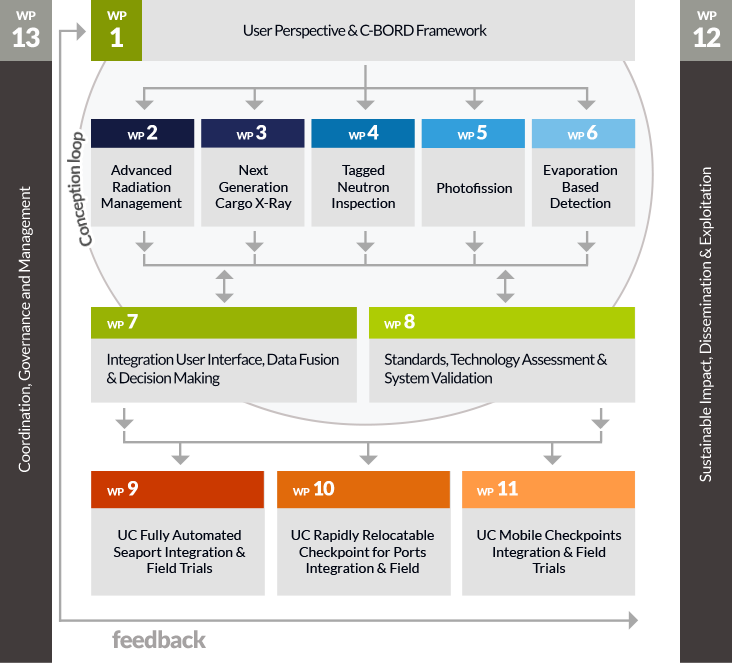

- Develop a multi-disciplinary ecosystem interfacing different non-destructive passive and active techniques for container inspection solutions

- Fusion of the datasets and develop a unified viewer compatible with the end user expectations & constraints

Objectives

Within the project, the assessment of the following five technologies as well as of the combined C-BORD system is planned regarding radiation portal monitors (RPM) as passive scanning technologies for radioactive materials, next generation X-ray scanning, Rapidly Re-locatable Tagged Neutron Inspection System (RRTNIS) utilizing a neutron generator as an active method of detection, Photofission, and evaporation based detection technologies.

The assessment and validation process of the technologies is meant to demonstrate:

- The suitability of the modified and enhanced technologies for deployment in the container freight context.

- The combination of several technologies for reliable detection of radioactive material, explosives, chemicals, drugs, and tobacco hidden in cargo containers.

Particular attention is given to active detection methods which cannot be applied to pedestrians or vehicles for health and ethical reasons and are only be used with regard to objects. As such, it must be ensured that no danger is posed to the public when applying these methods.

Assessment Activities

During the assessment the current characteristics of the integrated NII detection systems based on different technologies will be compared with the defined requirements which were developed at the beginning of the project in cooperation with end users. This will be done by a comprehensive analysis of the different C-BORD NII technologies, the results of the performed test measurements, field validation trials under real life conditions, and end user input.

- End user input: The end user perspective will be taken into account via interviews and questionnaires with customs partners and Advisory Group members. A standard approach for all tasks concerning Standards, Technology Assessment and System Validation will be elaborated.

- Test measurements: Results from tests performed during the technical development as well as different test measurements performed directly in cooperation with the technology developers are considered to check if the specific end user requirements defined in the beginning of the project are fulfilled. The technology’s ability to detect, to identify or at least categorise different kinds of agents/material and the time needed for this will be important aspects to assess.

- Field validation trials under real life conditions: Results from the Use Case field trials will be used as an important basis for the overall assessment of the technologies as well as for the full C-BORD solution. There will be three field validation trials performed: NII scanning for big automated terminals in Rotterdam seaport, for relocatable installations in Gda?sk seaport, and mobile installations for road checks at a land border in Hungary. These trials will be run both to assess and evaluate the project results in a realistic environment.

Assessment results obtained from laboratory testing in the earlier stages of the C-BORD project will be fed back to developers for making further improvements and will be used to support the planning and execution of the field validation trials to test the C-BORD system’s ability to detect the materials and substances targeted.

Furthermore, based on the results from the assessment activities during the project, recommendations on existing standards applied to the assessed technologies will be collected and suggestions for modifications of these standards to meet the demands of end users will be elaborated.

Expected Results

- The evaluation process of the technologies and the entire C-BORD system according to current European and American standards will result in specific statements about the reliability of the system and its components to detect to the material in question in cargo containers.

- In this context, the licensing procedure for the deployment of technologies in the use case trials will serve as a best case approach to take into consideration all safety and health risks.

C-BORD Use Cases

Proof of capability through live field trials in three use cases under real conditions at different border control points

- Site: Rotterdam port

- Operational context: Fixed installations

- Toolbox: Advanced Radiation Management / Next Generation Cargo X-Ray / Evaporation Based Detection / Tagged Neutron Inspection / Photofission

- Site: Gdansk port

- Operational context: Relocatable

- Toolbox: Advanced Radiation Management / Next Generation Cargo X-Ray / Evaporation Based Detection / Tagged Neutron Inspection

- Site: Hungarian land border

- Operational context: Mobile

- Toolbox: Advanced Radiation Management / Next Generation Cargo X-Ray / Evaporation Based Detection